Elevate Your Business with High-Quality Vacuum Press Silicone Membranes

In the rapidly evolving landscape of manufacturing, technological advancements are key to staying ahead of the competition. Among these innovations, vacuum press silicone membranes have gained significant recognition for their exceptional performance, durability, and versatility. As a leading provider in the industry, silicone-membranes.eu offers a comprehensive selection of silicone membranes for sale and a premium rubber membrane shop designed to meet the diverse needs of modern businesses.

What Are Vacuum Press Silicone Membranes?

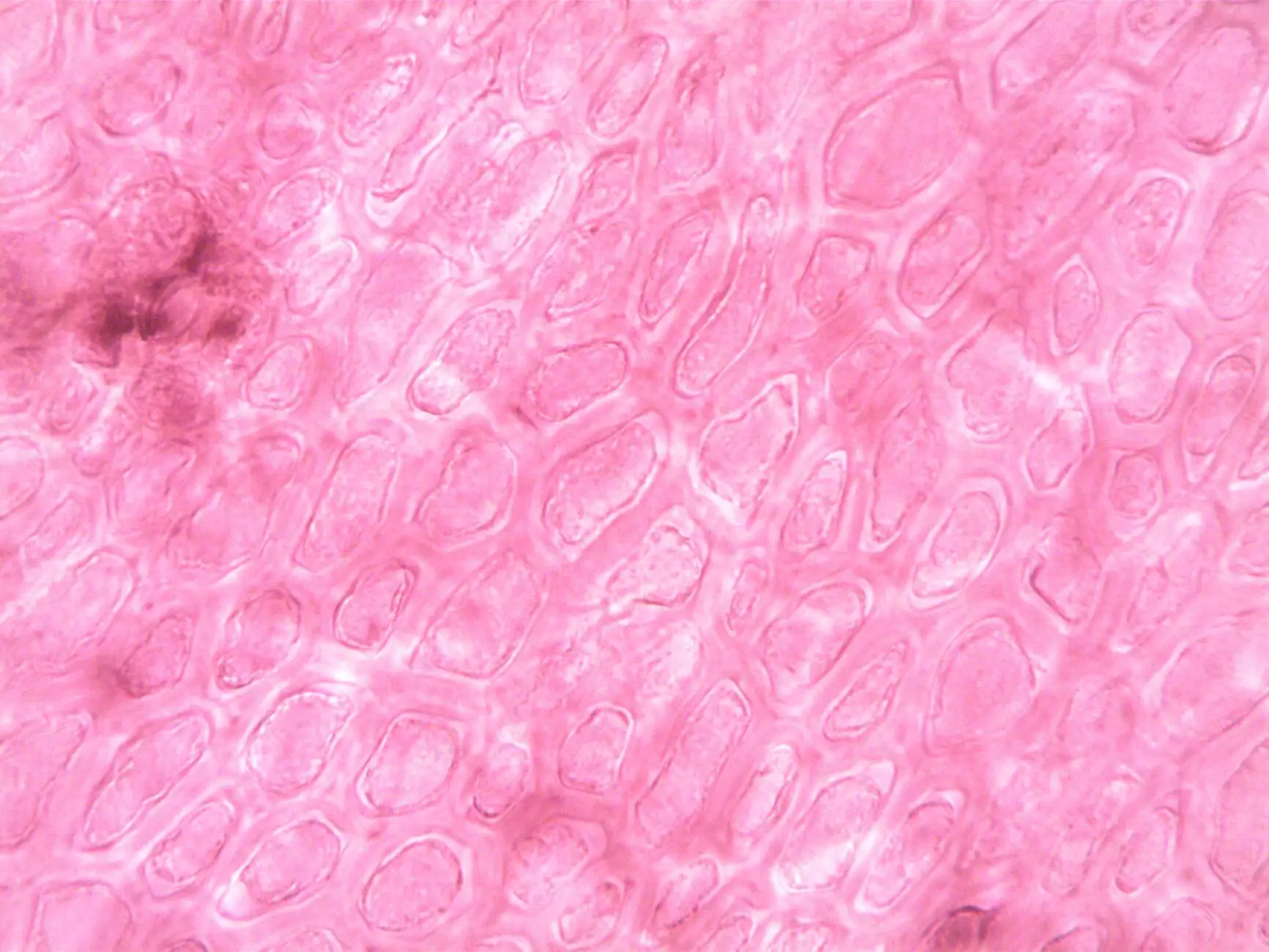

Vacuum press silicone membranes are specialized flexible sheets made from high-quality silicone rubber. These membranes are engineered to function in vacuum forming, pressing, laminating, and various other industrial applications. They act as an interface between the press equipment and the manufactured product, ensuring uniform pressure distribution and precise results.

These membranes are renowned for their superior thermal stability, chemical resistance, and flexibility, making them suitable for processes requiring consistent performance across a wide temperature spectrum. Their design allows them to conform tightly around objects, enabling complex shapes and detailed features to be produced with precision.

The Business Advantages of Using Vacuum Press Silicone Membranes

1. Superior Product Consistency and Quality

By utilizing vacuum press silicone membranes, manufacturers can achieve uniform pressure application across their workpieces. This consistency reduces material wastage and enhances the quality of outputs such as molded items, laminated panels, or composite structures.

2. Increased Production Efficiency

These membranes significantly reduce cycle times owing to their rapid heat transfer capabilities and easy handling. The high thermal conductivity of silicone membranes allows for faster heating and cooling cycles, leading to higher throughput and cost savings.

3. Durability and Long-Term Cost Savings

Constructed from premium silicone, these membranes resist aging, tearing, and chemical degradation. This durability extends the lifespan of the membranes, thereby minimizing replacement costs and ensuring long-term investment value.

4. Versatility Across Industries

- Automotive Manufacturing: For composite bonding, window laminates, and complex part molding.

- Electronics: In encapsulating components and producing flexible circuits.

- Medical Devices: For manufacturing precise silicone-based components.

- Furniture and Interior Design: In lamination and surface finishing processes.

Choosing the Right Silicone Membrane for Your Business

Factors to Consider

- Size and Shape: Depending on the dimensions of your workpieces, select membranes that can accommodate your molds or products.

- Thickness: Thicker membranes offer greater durability, whereas thinner options provide enhanced flexibility for complex shapes.

- Temperature Range: Ensure the membrane can withstand your process temperatures without degradation.

- Chemical Compatibility: Select membranes resistant to the chemicals used in your production environment.

Customizing Silicone Membranes

At silicone-membranes.eu, we offer tailored solutions designed to meet specific industrial needs. Customization options include bespoke sizes, thicknesses, and even special formulations to enhance chemical resistance or thermal stability—helping your business optimize performance and efficiency.

The Role of a Reliable Rubber Membrane Shop in Business Growth

A reliable rubber membrane shop such as ours offers unparalleled expertise and access to an extensive inventory of silicone membranes for sale. Partnering with a trusted supplier ensures that you receive products that meet strict quality standards, delivered promptly, and supported by professional technical advice.

By sourcing your membranes from a reputable manufacturer or distributor, your business gains:

- Consistency and dependability in product quality.

- Access to extensive product varieties to suit diverse process requirements.

- Technical support and customization services.

- Competitive pricing through bulk purchasing and partnerships.

Innovative Applications and Future Trends in Vacuum Press Silicone Membranes

1. Advances in Material Science

Material scientists are continuously improving silicone membrane formulations to enhance thermal performance, mechanical strength, and chemical resistance. The integration of nanomaterials and other composites is opening new possibilities for industrial applications.

2. Automation and Smart Manufacturing

Modern vacuum press systems are integrating IoT sensors and automation controls to monitor membrane performance in real-time, predict maintenance needs, and optimize process parameters dynamically. These innovations ensure minimal downtime and maximize productivity.

3. Sustainable Manufacturing Practices

Eco-friendly silicone formulations, recycling programs for used membranes, and energy-efficient heating solutions contribute to a greener manufacturing environment. Businesses adopting these innovations benefit from cost savings and improved corporate social responsibility.

Why Choose Silicone-Membranes.eu for Your Business Needs

As an established provider in the field, silicone-membranes.eu offers:

- Premium quality silicone membranes sourced from top manufacturers.

- Comprehensive product range suitable for various industrial sectors.

- Expert technical guidance to help select and customize the ideal membrane.

- Fast and reliable delivery services to support your production schedules.

- Competitive prices and flexible purchasing options.

Conclusion: Unlocking Business Potential with Vacuum Press Silicone Membranes

Investing in vacuum press silicone membranes is a strategic move for businesses seeking to improve their manufacturing processes, enhance product quality, and reduce operational costs. Their exceptional performance characteristics make them indispensable tools across a multitude of industries, from automotive to electronics.

Partnering with a trusted supplier like silicone-membranes.eu ensures access to top-tier silicone membranes for sale and comprehensive support. Staying ahead in today’s competitive market requires embracing innovative solutions—vacuum press silicone membranes are undoubtedly a vital component of this progress.

To explore the full range of possibilities, contact us today and discover how our high-quality rubber membranes can transform your manufacturing capabilities and business success.